Volume 7, Issue 1- March 2014

The Supplier

Steel and Ductile Iron: The New Wood Pole

Many utilities in the Rocky Mountain area have begun to look at the total ownership costs of using steel or ductile iron poles in place of wood either for all new applications or for selected applications (i.e. critical feeder lines, critical poles, equipment poles, crossing poles, angle or deadend poles etc.). Carbon Power and Light in Wyoming has used all steel poles since the 1990's in order to harden their system (improving reliability and avian protection). Tucson Electric and Arizona Public Service have switched from wood to steel in order to provide improved reliability and solid long-term value.

Advantages of steel poles include; a life expectancy of 60-75+ years (twice that of wood), can be fabricated with uniform strength and dimensions (accepts the same hardware all the time) and conforms to ASTM specs with drilling completed at the factory, 50-70% less weight, the entire pole can be recycled at the end of its useful life, no pole shrinkage (no re-tightening of hardware), the poles do not experience a loss of strength due to aging, infestation or fires leading to sudden failures, no expensive inspection or treatment programs required, freight charges are less expensive (due to many more steel poles being able to ship on a truck as compared to wood), and the potential to carry heavier loads and increase span lengths. Rather than breaking, steel poles will bend, leaving lines intact during a severe wind or ice storm, thus no cascading of poles and lines. In fact when combined with PUPI fiberglass crossarms and Hendrix polymer insulators, the line has an excellent aesthetic appearance as well as an extended life. All items are RUS approved.

For a complete presentation on the advantages of steel or ductile iron poles (less expensive than steel), please see your WUE account representative. A full total ownership cost analysis/justification can be performed by WUE with additional input from your utility. For references on the use successful of steel poles, please feel free to call David Cutbirth at Carbon Power and Light.

WUE UPDATE

Ermco has redeemed a portion of their outstanding capital credits with WUE. In turn, WUE has recently (early February) redeemed most of their outstanding 2007 capital credits by sending appropriate checks to members holding those certificates. Only from cooperatively member owned companies like Ermco and WUE can you receive capital credits and then have them redeemed for cash!

WUE has increased their inventory levels to $11M in order to support the increased demand from members for construction materials. Manufacturers have announced price increases for 2014 ranging from 0-4%. WUE continues to aggressively negotiate and leverage manufacturers for low material prices

WUE recently purchased a new Kenworth tractor to add to their growing fleet The new tractor was needed due to ever growing stock sales out of their two warehouses. For the first time in their history, on November 20, WUE had 6 tractor trailer rigs and two stake trucks delivering materials to members in three states.

Electromark will perform an audit of any utility's safety labels to assure that they comply with all current ANSI specifications. See your WUE account manager if you are interested in having an audit completed.

New Products Update

Thomas and Betts Elastimold is proud of their new lighter weight (33% lighter), modular three phase configuration recloser with solid dielectric insulation and vacuum bottle interruption, integral load-side voltage sensors and fully compatible SEL controls. The SEL control typically includes the following: Overcurrent protection - fast and delay curves, Sensitive earth fault, Complete metering, Recloser wear monitor, Fault Locator, Flexible control logic and integration, Supervisory control and data acquisition ready, Load profile The unit is available in 15KV, 27KV and 38KV voltages with higher continuous current ratings (800A) and higher BIL values (150KV BIL for 15KV and 25KV applications and 170KV BIL for 35KV applications) than competitor's units. The EPDM/Silicon rubber bushings dramatically exceed required creep values for level IV very heavy pollution levels. Operating temperatures are -40 degree C to 65 degree C.

Please see your WUE account manager for a full presentation. Elastimold has set the bar higher in available recloser technology.

BENEFITS OF ALUMINUM-CLAD GUY STRAND

ALUMINUM-CLAD STEEL GUY STRAND (8M and 10M) has become the industry standard for utility installations requiring guy strand in many areas of the country. This type of guy strand offers superior corrosion resistance due to the aluminum cladding. The aluminum layer is extruded over the steel core, forming a tight bond with the steel. The thickness of the aluminum cladding is at least 10% of the radius of the individual wires making up the cable. In comparison, the zinc layer on galvanized steel guy strand is applied by dipping the steel wire in a bath of molten zinc and the thickness of the protective layer is significantly less than it is for aluminum-clad steel.

Various manufacturers of aluminum-clad guy strand have had comparative corrosion resistance tests conducted by an independent laboratory. These show that after 500 hours of salt spay exposure, the corrosion resistance of aluminum-clad steel is far superior to that of galvanized steel.

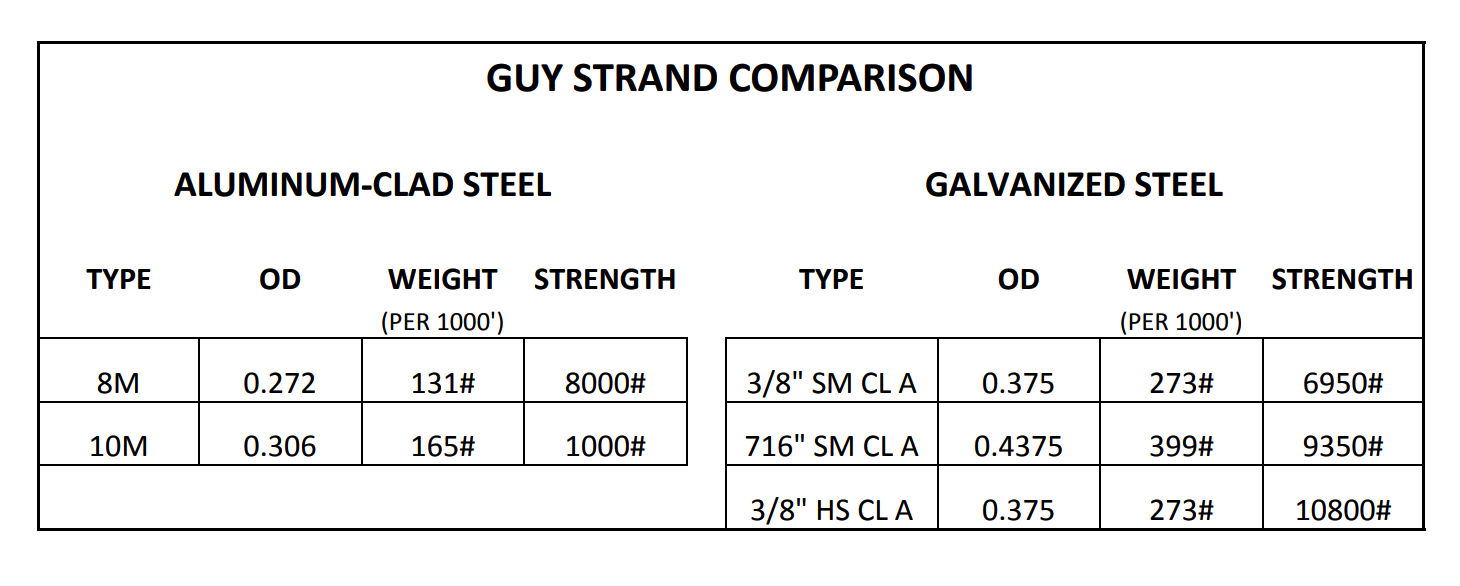

The other benefit of aluminum-clad guy strand is the lighter weight and greater strength per unit length. For example, 3/8 inch (SM) galvanized steel guy strand weighs 273 lb. per thousand feet while 7/16 inch diameter (SM) galvanized weighs 399 lb. per thousand feet. In comparison, 10M aluminum-clad steel (0.306” diameter) weighs 165 lb. per thousand feet and has a higher breaking strength (10,000 lb) than the 7/16 (SM) galvanized (9,350 lb. strength). The 8M (.272 inch diameter) weighs only 131 lb. per thousand feet with a breaking strength of 8000 lbs., thus a better option than the 3.8” sm galvanized option.

The following chart summarizes the characteristics of each type of guy strand stocked by WUE. Your line crew may prefer to try the aluminum-clad (sometimes called alumaweld) option manufactured by AFL. In stock for immediate shipment - your crews won’t go back.

Product Usage Update

The use of Cooper sectionalizing loadbreak/loadmake switches in three phase transformers has become a requirement in many specs. These switches are used in both underground residential applications with loop feed and in three-phase commercial/ industrial installations where the ability to use an alternate source of power is necessary. They can also be used to switch on and off a primary cable tap on a transformer or to facilitate the final checkout of new URD installations before they are put into service allowing cable sections to be energized independently. Because the switch is installed near the transformer core/coil assembly, cable capacitance is minimized. Thus when all three phases are switched simultaneously, the likelihood of ferroresonance is greatly reduced. Six different blade configurations (suggest T blade Design) for one, two or three pole connections is available. Continuous current ratings are 200, 300 and 600A. Available in 15, 25 and 35 KV.